Horizontal well gas-liquid-sand intelligent control and monitoring technology

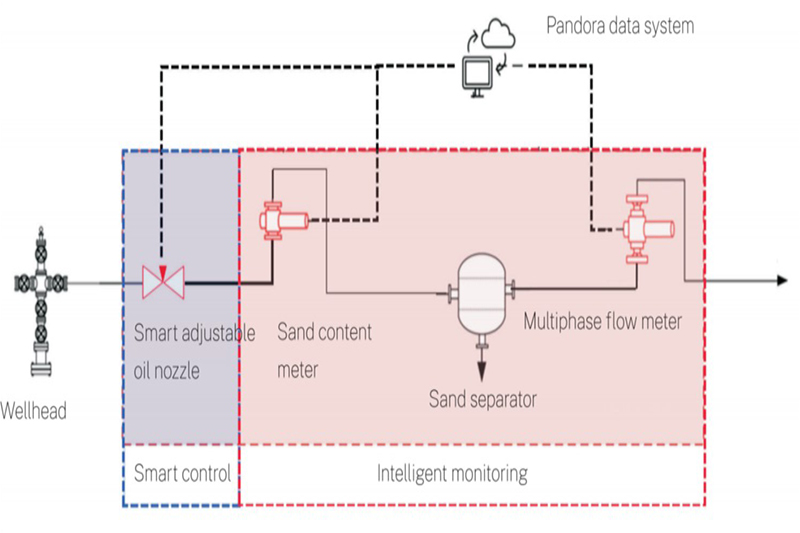

In the post-fracturing flowback stage of horizontal wells, which is a crucial link between completion and production, the rationality of the flowback system significantly impacts fracturing effectiveness assessment and subsequent production efficiency. The intelligent control and monitoring technology for gas-liquid-sand in horizontal wells can manage pressure drops during flowback, control sand in the formation, optimize flowback systems, monitor Gas-Oil Ratio (GOR), and assess fracturing effectiveness during the flowback process.

- Introduction

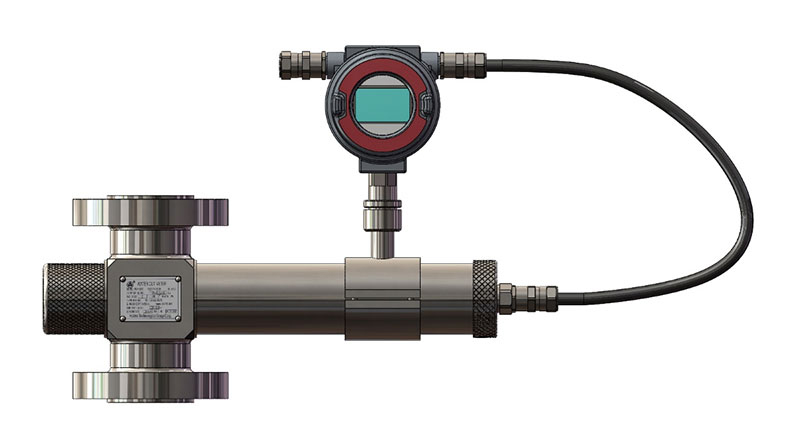

- Components

- Specifications

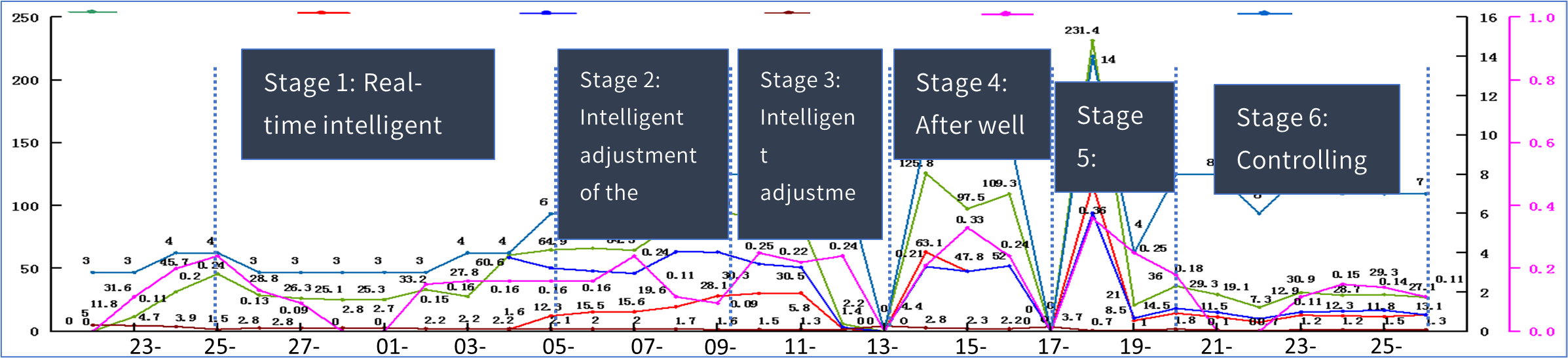

- Case

Oil and Gas Services

Oil and Gas Services