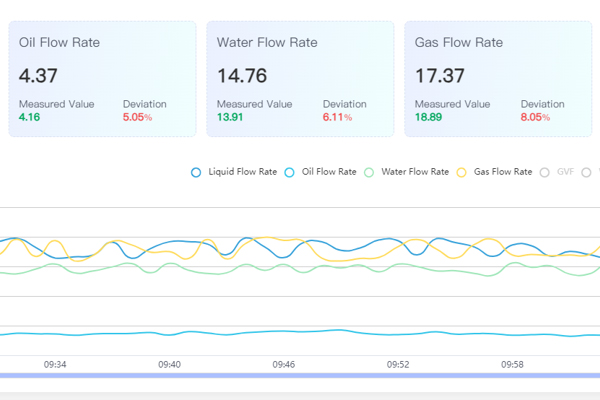

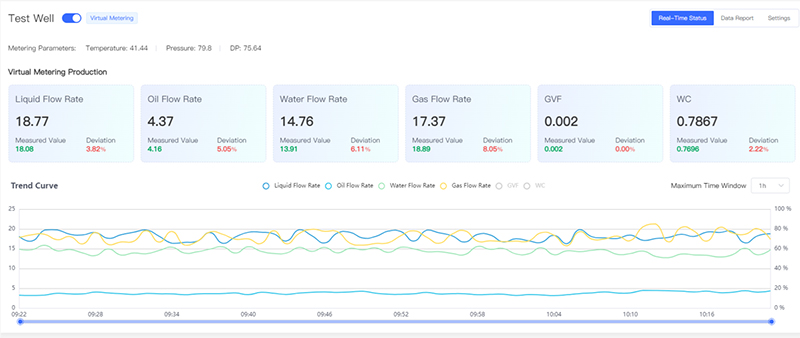

Virtual Metering

Virtual metering allows for real-time inference of current liquid, oil, water, and gas flow rates, as well as gas and water content information, without the need for physical flow meters. This is achieved by integrating other well parameters such as wellhead temperature, pressure, differential pressure, etc., through specified models & algorithms. This approach reduces the investment in hardware equipment and decreases the complexity of field facility deployment. The model can be trained and optimized based on historical measurement data to improve accuracy, thereby enhancing data quality and value.

- Introduction

- Benefits

- Features

Integrated Production

Integrated Production