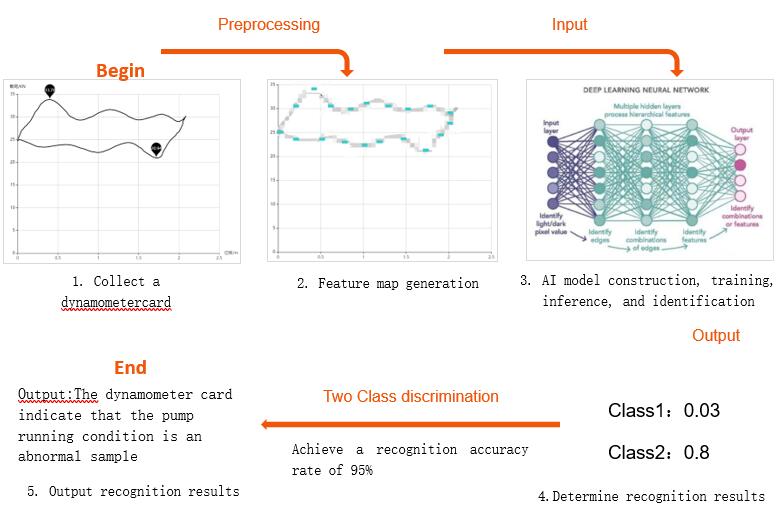

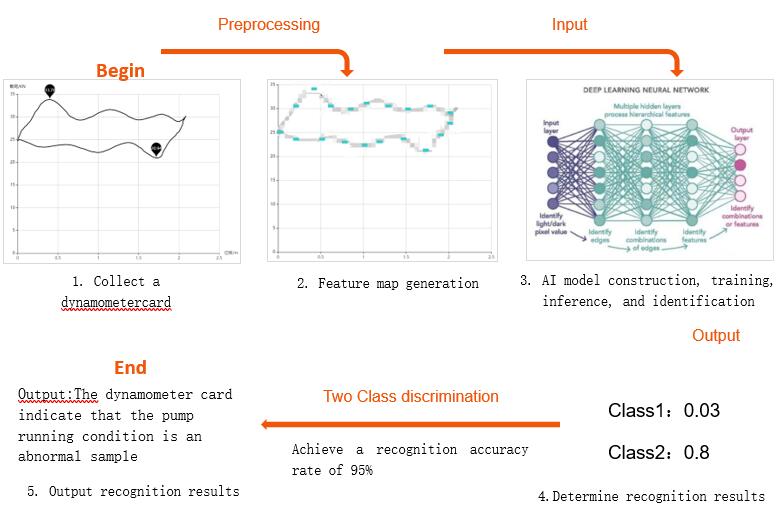

Using a dynamometer card analyzer, the dynamic liquid level and production rate of an oil well can be efficiently and accurately calculated online in real-time to predict the operational status of the pump jack. This replaces the traditional method of using a fluid level instrument to measure the well’s dynamic liquid level, optimizing equipment safety, reducing production equipment costs, and extending the service life of the equipment.

Intelligent Recognition

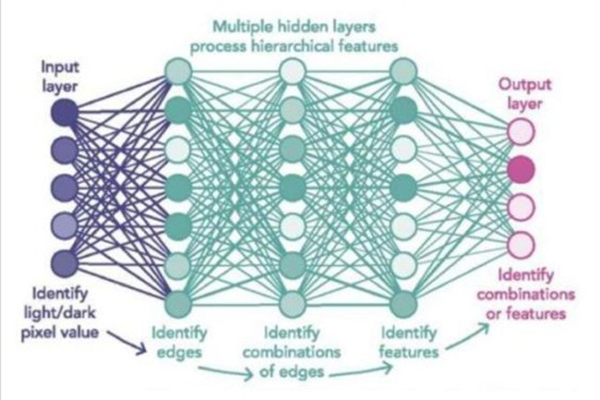

The dynamometer card analyzer independently collects signals synchronously, preventing distortion caused by asynchronous signals. The analyzer extracts the dynamometer card graphs and various features from the collected signals. An intelligent recognition module for the pump jack's dynamometer card, based on a fusion of multiple algorithms in deep learning and machine learning, can identify the current operating condition of the pump jack and provide real-time alerts for abnormal situations. In this module, the accuracy rate for intelligent recognition of normal and abnormal card conditions is 96%, while the recognition accuracy across multiple operating conditions is 85.6%.

Dynamometer Card Correction

If a user believes that the current recognition result of the dynamometer card is incorrect, they can manually modify the result to a correct one and submit the change. If the user finds that the current type of dynamometer card does not fall within the 17 available conditions, they can input the correct type and submit the modification.

Integrated Production

Integrated Production