Haimo Technologies Leads China's Intelligent Manufacturing to Shine at 2025 OTC Exhibition

Classification:News Reading number:2927 update time:2025-05-13

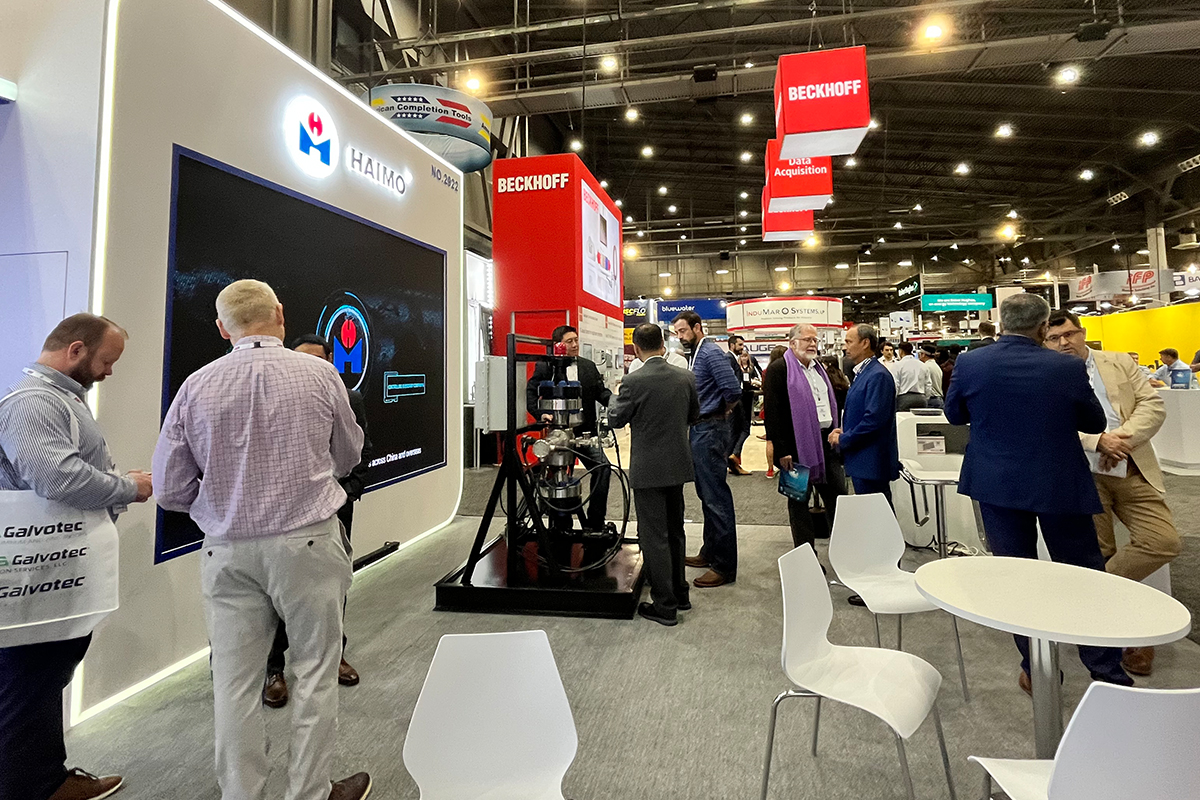

Houston, May 5-8, 2025 – The Offshore Technology Conference (OTC), the world's premier event for the oil and gas industry, was grandly held in Houston. As the largest and most professional energy equipment and technology exhibition, OTC brought together industry leaders and innovators from around the globe. As one of the leading enterprises in China's energy sector, Haimo Technologies has been invited to participate in exhibitions for many consecutive years. This year, it made a stunning appearance with its independently developed high-end equipment for oil and gas fields such as multi-phase flowmeters and hydraulic ends of fracturing pumps, as well as digital solutions, demonstrating the hardcore strength of "Made in China" to global clients!

Cutting-Edge Solutions Turn Heads, Global Market Responds with Demand

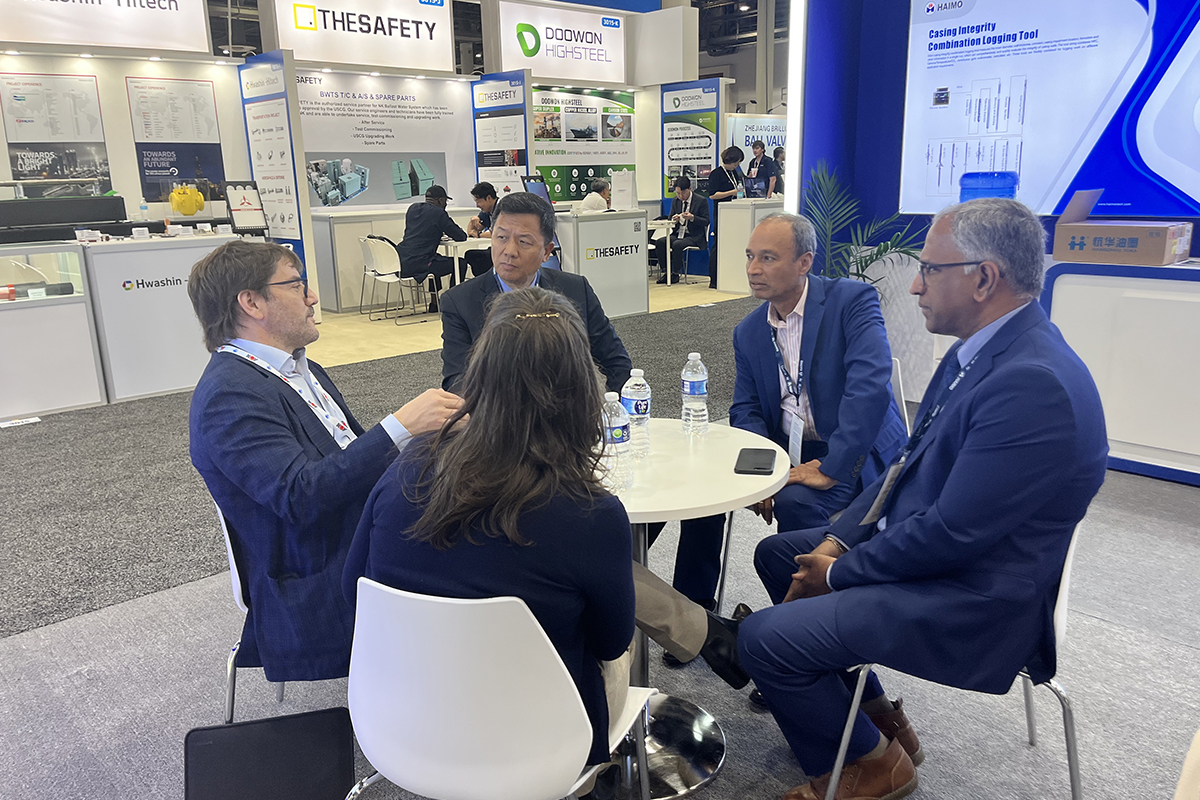

During the exhibition, the booth of Haimo Technologies was crowded with people. Its multiphase metering products and digital solutions garnered significant interest from international peers. Oil companies, technical experts, and partners from the Middle East, North America, Europe, and other regions highly praised the accuracy, reliability, and innovation of Haimo's products. Many clients expressed their intention for deep cooperation on-site, which further demonstrates the brand influence of Haimo Technologies in the international market.

Leading Technology, Empowering Global Oil & Gas Development

At this year's OTC, Haimo Group made a remarkable appearance with its subsidiaries, presenting a full range of innovative products and technical solutions covering the entire oil and gas exploration and production chain. The group stood out as one of the most eye-catching exhibitors.

The short-section multiphase flowmeter, a key product launched by Haimo Technologies, adopts a new generation of dynamic measurement algorithm, which has innovatively solved the problem of precise measurement under complex working conditions such as high gas content (0-100%) and high water content. This product has been successfully applied to multiple onshore oil and gas fields in the Middle East, North America, etc., as well as offshore oil and gas platforms in the South China Sea, East China Sea, etc. Its outstanding stability and accuracy have won wide recognition from international clients.

Most striking is Haimo Technologies' innovative subsea multiphase flowmeter. This product, specially designed for deep-sea operations, has a maximum working water depth of up to 3,000 meters and has been certified by DNV. It can adapt to harsh underwater application environments, achieve online real-time measurement, and provide a reliable measurement solution for the development of deep-sea oil and gas fields.

Sitan Instrument Co., Ltd., a subsidiary of Haimo, exhibited its downhole casing inspection tool (also known as the casing deformation combination logging tool). This tool can comprehensively and efficiently evaluate casing integrity in a single run, measuring parameters such as inner diameter, wall thickness, corrosion, cracks, perforations, damage orientation, and formation data. It combines multiple logging instruments, including multi-arm calipers, electromagnetic flaw detectors, thickness gauges, gyro continuous inclinometers, and gamma/temperature tools, with flexible configurations to meet varying logging needs.

Shanghai Qinghe Machinery Co., Ltd., another Haimo subsidiary, showcased its Enduro Frac pump fluid end product. Made from high-strength stainless steel and optimized with self-reinforcing surface treatment for corrosion resistance, this product maintains exceptional durability under extreme conditions—such as 20,000 psi pressure, acidization, and high sand ratios—while being compatible with various frac truck models for conventional and unconventional oil and gas extraction.

In oilfield engineering services, Sitan Oil and Gas Engineering Services Co., Ltd. demonstrated its quantum dot tracer production profiling technology and digital flowback solutions. These technologies enable efficient, precise, and long-term intelligent monitoring, providing innovative approaches for horizontal well production profiling and flowback control while significantly reducing carbon emissions compared to traditional methods.

Future Outlook: Enhancing Worldwide Deployment, Shaping a Greener Energy Ecosystem

In the future, Haimo Technologies will continue to increase its investment in research and development, promote the technological upgrade of oil and gas equipment, and deepen cooperation with international partners to provide smarter and greener products and services for the global energy industry. Through OTC's global platform, Haimo Technologies has once again proven to the world that Chinese innovation is driving powerful momentum for the future of energy!

Hot News

-

Haimo Technologies Leads China's Intelligent Manufacturing to Shine at 2025 OTC Exhibition

Houston, May 5-8, 2025 – The Offshore Technology Conference (OTC), the world's premier event for the oil and gas industry, was grandly held in Houston. As the largest and ...

-

HAIMO Successfully completed the Factory Acceptance Test for ARAMCO Offshore Project

On April 30, 2020, Haimo Energy Technology successfully completed the Factory Acceptance Test (FAT) for ARAMCO offshore project and the units are now ready for dispatch.

-

Embracing Oil & Gas Industry 4.0 - Haimo Technologies Group Corp. at ADIPEC 2019

ADIPEC 2019, the Oil & Gas industry’s global conference& exhibition, was held this year from 11-14 November, 2019 at the Abu Dhabi National Exhibition Centre (ADNEC), UAE.

News

News