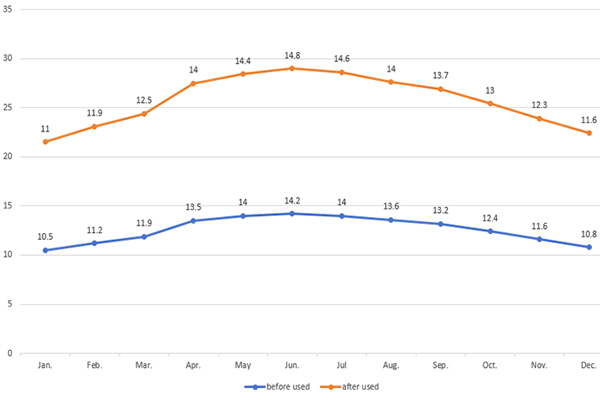

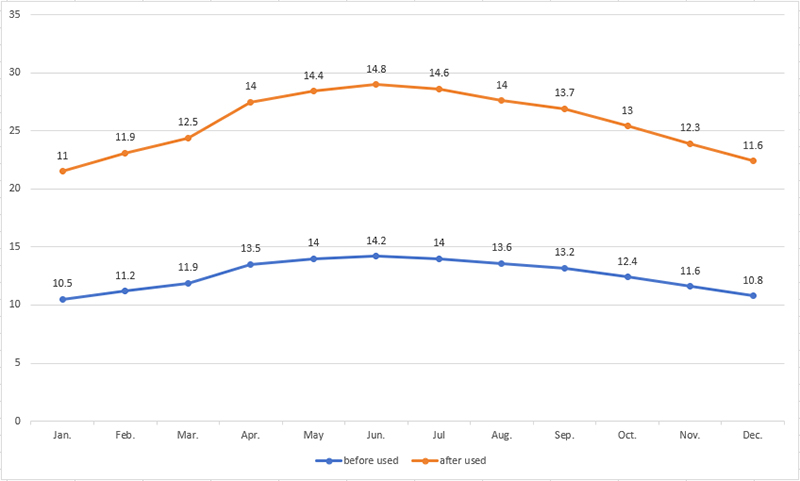

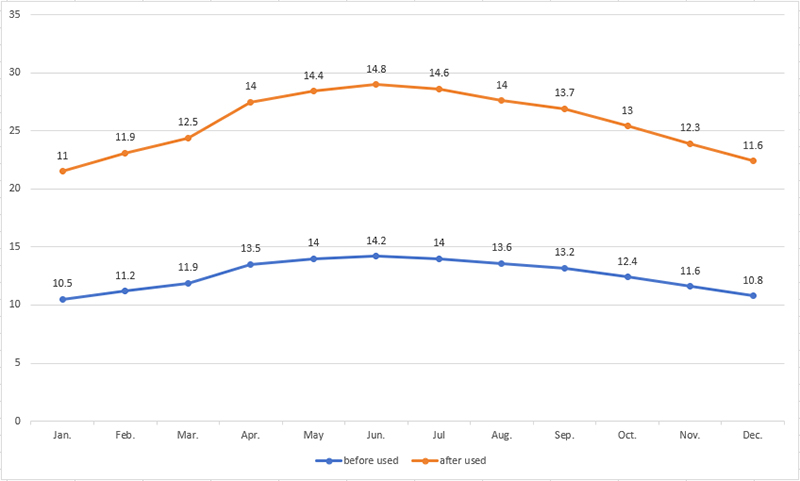

By collecting dynagraph data with a dynamometer, the dynamic liquid level is estimated. Optimization algorithms are applied to intelligently control the rod pump stroke frequency, increasing the oil well's liquid production.

The system has developed intelligent optimization control technology based on a comprehensive diagnosis of oil well production parameters. This technology integrates online testing, dynagraph data acquisition, diagnostic communication for rod pump wells, and gas lift control.

For medium- and high-yield wells, diagnostic results from the dynagraph are used to calculate the dynamic liquid level. By analyzing and diagnosing well conditions, and combining parameters such as the optimal submersion depth of the pump and flow pressure, the system determines optimal operating parameters to maximize reservoir potential. This approach helps resolve production challenges, improve economic returns, extend pump inspection cycles, and intelligently control rod pump stroke frequency through optimization algorithms, ultimately enhancing oil production.

Integrated Production

Integrated Production