Research and development background

In the later stages of natural continuous production period, as the gas field develops and the reservoir energy decreases, the gas production of gas wells continuously decreases, and the gas-liquid carrying capacity weakens. Without effective drainage measures, this can eventually lead to gas well water flooding, making it difficult to maintain stable gas production in the wells. Plunger gas lift for liquid unloading and gas production is currently widely recognized as the best drainage and extraction process in gas field development, and it is widely applicable to the mid-to-late stage development of gas well production.

Issues with conventional plungers include:

Unclear well conditions, unable to timely and accurately detect changes in downhole liquid levels.

Lack of understanding of the plunger operating patterns.

Inadequate drainage efficiency, leading to under utilization of gas energy.

Managing a large number of wells with accumulated liquids increases difficulty, reduces efficiency, and raises costs.

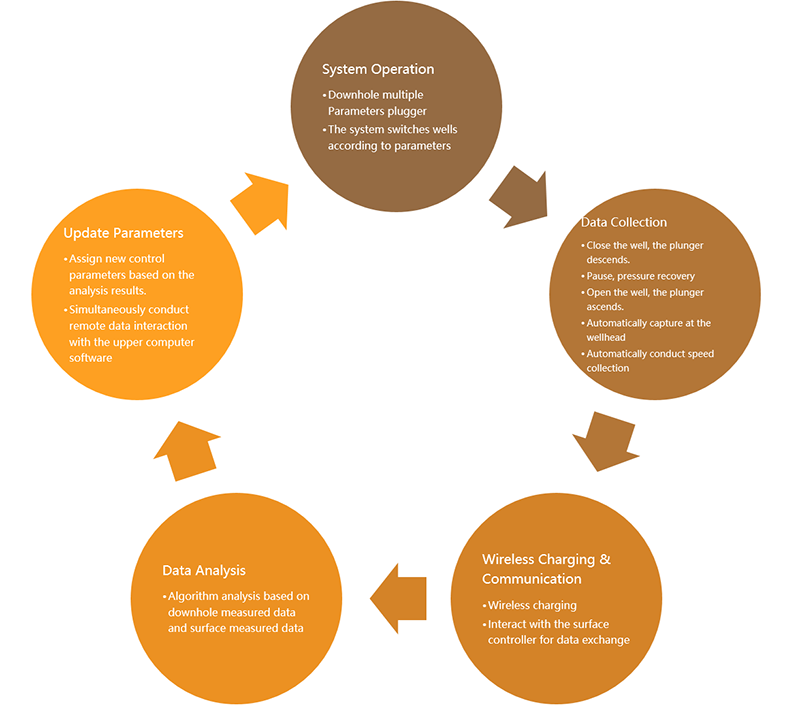

To address these challenges and improve intelligent management of gas field drainage, providing more accurate and effective guidance for gas well liquid unloading, the Haimo Intelligent Plunger Gas Lift System has been developed to replace conventional plunger gas lift technology.

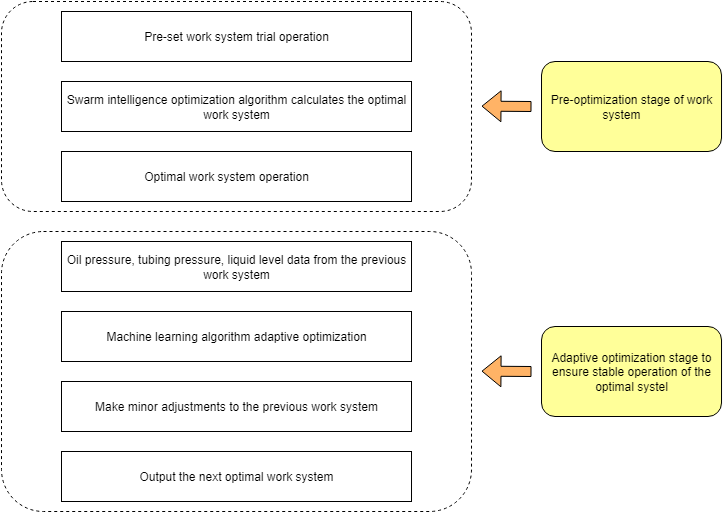

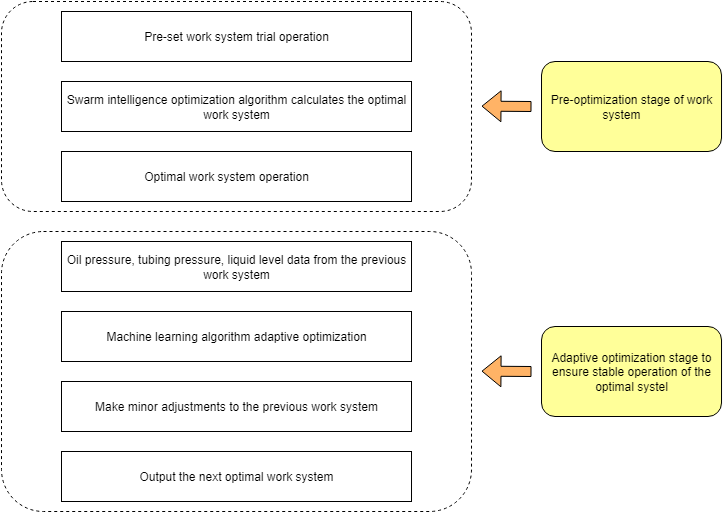

AI intelligent algorithm

Gas well optimization calculation process

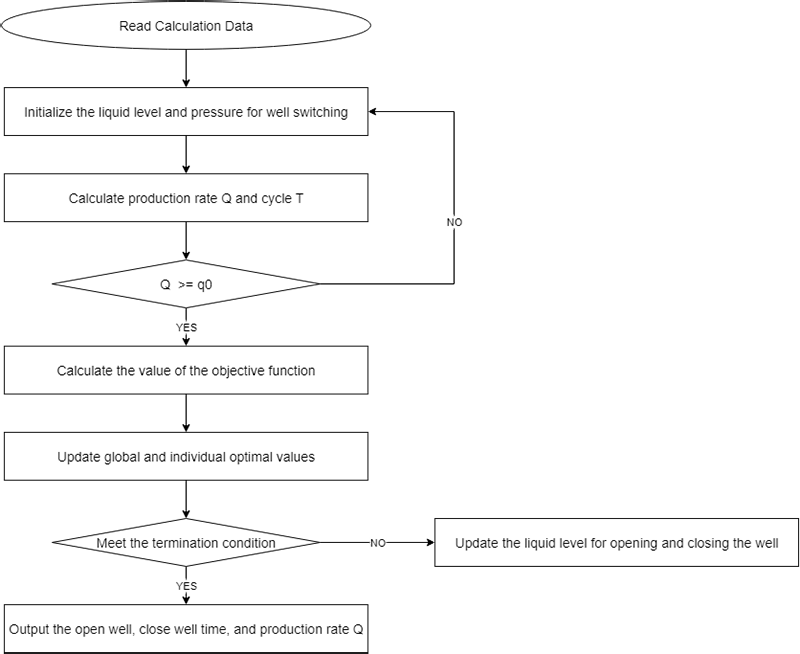

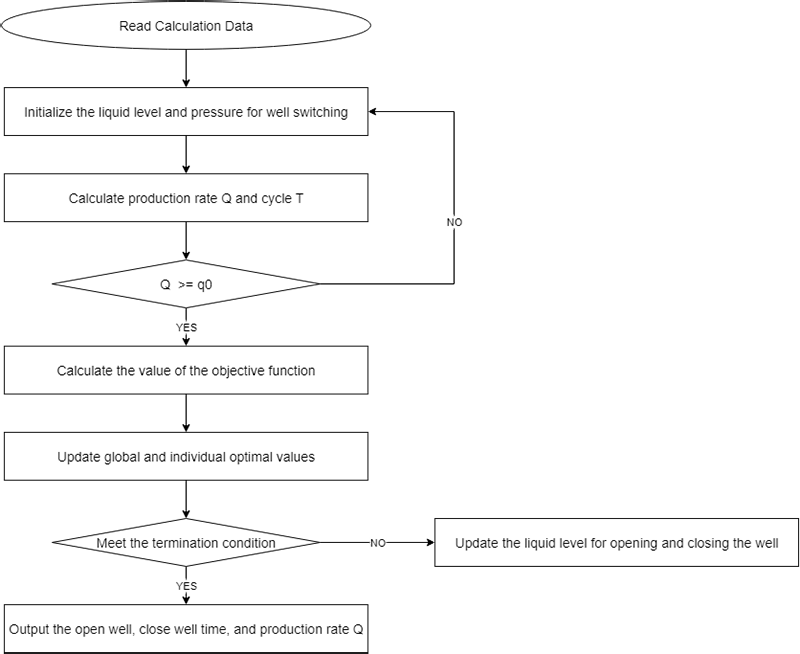

Plunger optimization algorithm process

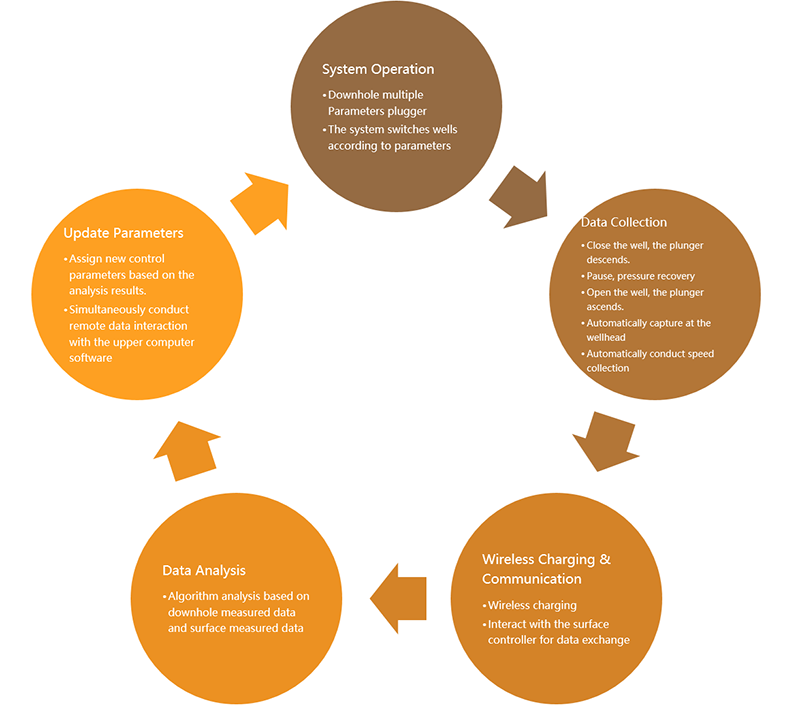

Integrated Production

Integrated Production