-

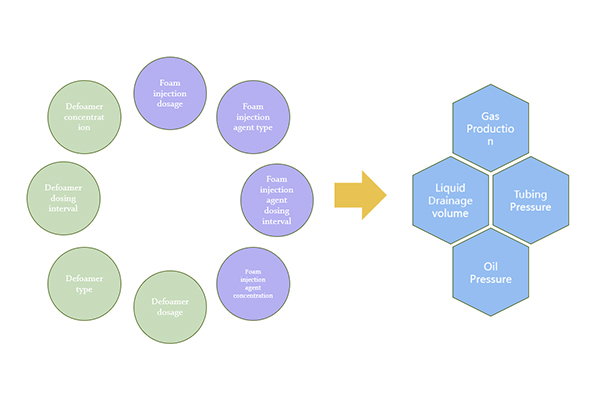

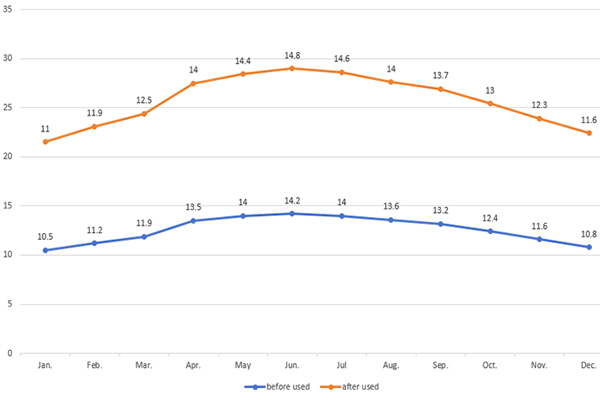

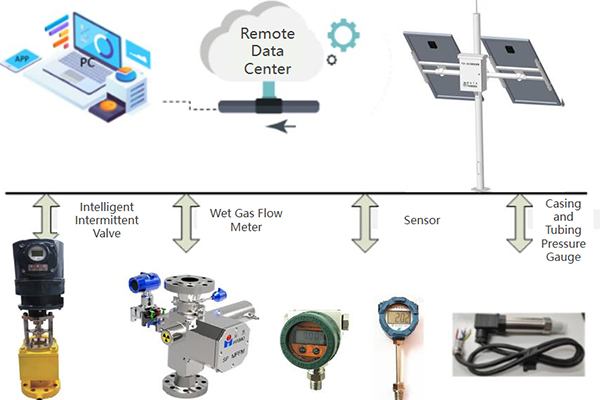

Foam drainage gas extraction is one of the most economically effective and widely used drainage gas extraction technologies in the later stages of gas field development. It has become an important method for increasing production and stabilizing production in water-containing gas wells.

-

By collecting dynamometer data, the dynagraph is used to calculate the dynamic liquid level. Utilizing optimization algorithms, the rod pump stroke frequency is intelligently controlled to increase the liquid production of the oil well.

-

By analyzing oil well production and fluid output using an intelligent intermittent pumping model, and comparing dynamic liquid levels, submergence depths, and tiered electricity pricing, the operation of the pump jack can be controlled to start or stop. This allows for staggered electricity usage for oil well production, achieving the goals of ensuring safe operation of the pump jack, reducing production costs (electricity expenses), and extending equipment lifespan.

-

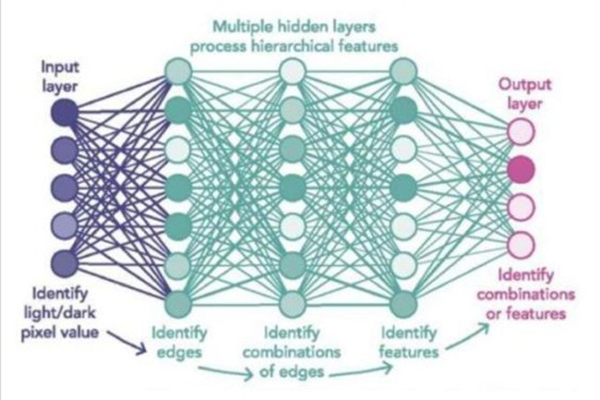

The dynamometer card of a pumping well is an important auxiliary tool for monitoring the production status of the well, which can effectively monitor the well conditions and the operation status of the pump. The intelligent pump card recognition model can replace oilfield production experts by accurately identifying pump failures and well abnormalities based on the shape of the dynamometer card, reducing the knowledge threshold for pump card recognition and improving the timeliness of identification.

-

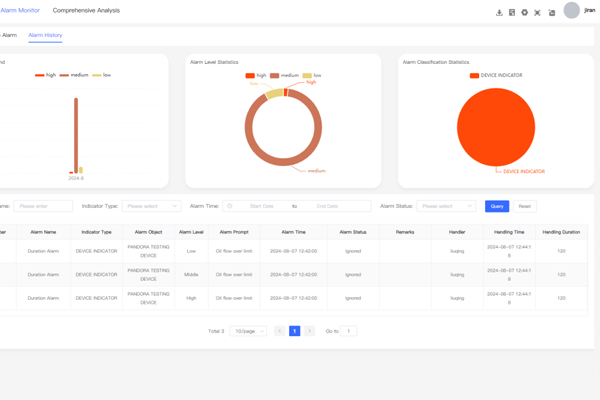

Equipment health management can intelligently monitor and alert abnormal operating conditions and equipment malfunctions, automatically sending email notifications to relevant personnel for timely intervention. This helps minimize losses resulting from abnormal operating conditions and equipment malfunctions.

-

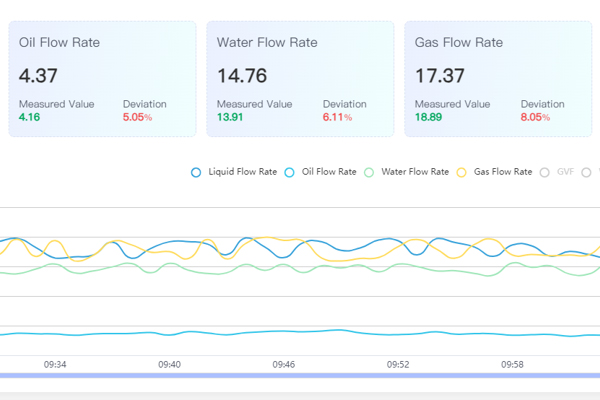

Virtual metering allows for real-time inference of current liquid, oil, water, and gas flow rates, as well as gas and water content information, without the need for physical flow meters. This is achieved by integrating other well parameters such as wellhead temperature, pressure, differential pressure, etc., through specified models & algorithms. This approach reduces the investment in hardware equipment and decreases the complexity of field facility deployment. The model can be trained and optimized based on historical measurement data to improve accuracy, thereby enhancing data quality and value.

Foam drainage gas extraction is one of the most economically effective and widely used drainage gas extraction technologies in the later stages of gas field development. It has become an important method for increasing production and stabilizing production in water-containing gas wells.

Foam drainage gas extraction is one of the most economically effective and widely used drainage gas extraction technologies in the later stages of gas field development. It has become an important method for increasing production and stabilizing production in water-containing gas wells. By collecting dynamometer data, the dynagraph is used to calculate the dynamic liquid level. Utilizing optimization algorithms, the rod pump stroke frequency is intelligently controlled to increase the liquid production of the oil well.

By collecting dynamometer data, the dynagraph is used to calculate the dynamic liquid level. Utilizing optimization algorithms, the rod pump stroke frequency is intelligently controlled to increase the liquid production of the oil well. By analyzing oil well production and fluid output using an intelligent intermittent pumping model, and comparing dynamic liquid levels, submergence depths, and tiered electricity pricing, the operation of the pump jack can be controlled to start or stop. This allows for staggered electricity usage for oil well production, achieving the goals of ensuring safe operation of the pump jack, reducing production costs (electricity expenses), and extending equipment lifespan.

By analyzing oil well production and fluid output using an intelligent intermittent pumping model, and comparing dynamic liquid levels, submergence depths, and tiered electricity pricing, the operation of the pump jack can be controlled to start or stop. This allows for staggered electricity usage for oil well production, achieving the goals of ensuring safe operation of the pump jack, reducing production costs (electricity expenses), and extending equipment lifespan. The dynamometer card of a pumping well is an important auxiliary tool for monitoring the production status of the well, which can effectively monitor the well conditions and the operation status of the pump. The intelligent pump card recognition model can replace oilfield production experts by accurately identifying pump failures and well abnormalities based on the shape of the dynamometer card, reducing the knowledge threshold for pump card recognition and improving the timeliness of identification.

The dynamometer card of a pumping well is an important auxiliary tool for monitoring the production status of the well, which can effectively monitor the well conditions and the operation status of the pump. The intelligent pump card recognition model can replace oilfield production experts by accurately identifying pump failures and well abnormalities based on the shape of the dynamometer card, reducing the knowledge threshold for pump card recognition and improving the timeliness of identification. Equipment health management can intelligently monitor and alert abnormal operating conditions and equipment malfunctions, automatically sending email notifications to relevant personnel for timely intervention. This helps minimize losses resulting from abnormal operating conditions and equipment malfunctions.

Equipment health management can intelligently monitor and alert abnormal operating conditions and equipment malfunctions, automatically sending email notifications to relevant personnel for timely intervention. This helps minimize losses resulting from abnormal operating conditions and equipment malfunctions. Virtual metering allows for real-time inference of current liquid, oil, water, and gas flow rates, as well as gas and water content information, without the need for physical flow meters. This is achieved by integrating other well parameters such as wellhead temperature, pressure, differential pressure, etc., through specified models & algorithms. This approach reduces the investment in hardware equipment and decreases the complexity of field facility deployment. The model can be trained and optimized based on historical measurement data to improve accuracy, thereby enhancing data quality and value.

Virtual metering allows for real-time inference of current liquid, oil, water, and gas flow rates, as well as gas and water content information, without the need for physical flow meters. This is achieved by integrating other well parameters such as wellhead temperature, pressure, differential pressure, etc., through specified models & algorithms. This approach reduces the investment in hardware equipment and decreases the complexity of field facility deployment. The model can be trained and optimized based on historical measurement data to improve accuracy, thereby enhancing data quality and value.

Integrated Production

Integrated Production